Six Sigma Green Belt practitioners who took a Lean Six Sigma Green Belt training have a firm grasp on the concept of “Operational Definition” in the measure phase and how it can help a project using the Six Sigma approach. Let’s define an “Operational Definition.” It can be defined as a clear and understandable description of what is to be observed and measured, such that different people collecting, using and interpreting data will do so consistently. It is a protocol that is followed in the MEASURE phase of the DMAIC process as discussed in Lean training courses. An operational definition is a clear, concise and detailed definition of a measure, that’s why it’s an important term for the measure phase. It is a concept to guide what properties will be measured and how they will be measured during the measure phase.

Attend our 100% Online & Self-Paced Free Six Sigma Training.

Defining Operational Definition of the Measure Phase

In Six Sigma Measure Phase, an operational definition is a precise definition of the specific “Y” to be measured. The “Y” could be “Small Y” or “Big Y”. It is often used for attribute data and describes a standard criterion to measure against. Operational definitions of the measure phase can also include text descriptions, pictures, photographs, models or samples. In the words of our Quality guru Deming:

“An operational definition is one that people can do business with…. It must be communicable, with the same meaning to vendor as to purchaser, same meaning yesterday and today…”

Why set a baseline?

Operational Definitions of the measure phase are used to baseline the performance. The purpose of the definition is to provide a single, agreed upon meaning for each specific “Y”. This helps ensure reliability, also the consistency is built in up-front during the measure phase. You need operational definitions when collecting all types of data in the measure phase. It is particularly important when a decision is being made about whether something is defective or not, whether a defect exists or not etc.

For example, how do you know if a package via courier has been delivered on time or not on time? The data collection will be meaningless if the definition of ‘On Time’ has not been specified. Therefore, operational definitions should be developed and tested before the data collection begins in the measure phase.

Measure Phase: Operational Definitions Worksheet

When collecting data, it is essential that everyone in the system has the same understanding and collects data in the same way. An Operational Definitions Worksheet (ODW) should, therefore, be made in the measure phase; before the collection of data begins. Any time data is being collected, it is necessary to define how to collect the data. Data that is not defined will usually be inconsistent and will give an erroneous result. It is easy to assume that those collecting the data during the measure phase understand what and how to complete the task. However; people have different opinions and views, and these will affect the data collection. The only way to ensure consistent data collection is by means of a detailed operational definition that eliminates ambiguity.

There is no single right method to document an operational definition. What people in the team or group agree to use for a specific purpose is documented via operational definition. The concept is simple enough for those who work on organizational change.

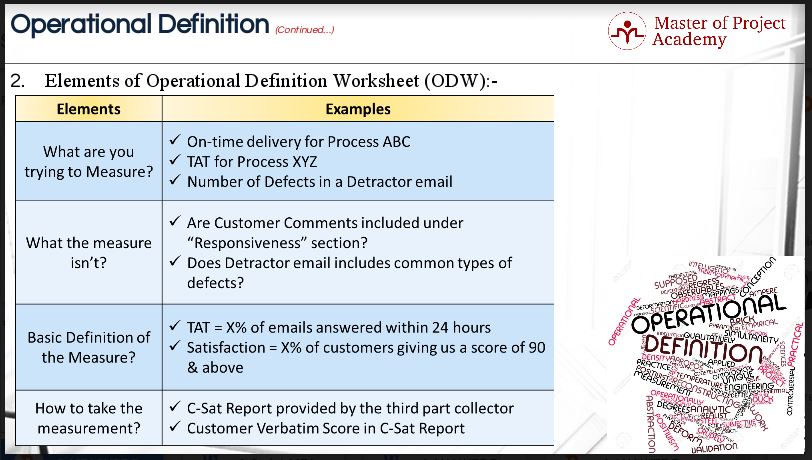

Measure Phase: Elements of Operational Definition Worksheet

An operational definition worksheet is a document or repository for recording operational definitions before the data collection activity begins in the measure phase. We’ve already got to know what an operational definition of measure phase is and should be. Now, let’s discuss the elements of operational definition worksheet. Please see the figure below to understand the elements of the operational definition worksheet. What are we trying to measure?

The first element of the operational definition worksheet refers to what we are trying to measure. Normally; in the measure phase, we try to measure process performance with the help of one or two process metrics. It could be on-time delivery, turnaround time, the number of defects etc.

Measure Phase: What is in and out of scope?

The second element of the operational definition worksheet refers to the scope of what we are trying to measure. In other words, we need to understand what is in-scope and out-of- scope for a specific measure. For example; the measure of ‘Responsiveness’ may not include customer verbatim and comments. An email that has been considered as a ‘Detractor’ or ‘Incorrect’ and/or ‘Incomplete’ may or may not include common and non-critical defects. In short, the project team has to define the scope of each parameter that they try to measure in the measure phase.

Measure Phase: How do we define the measure?

The third element of the operational definition worksheet refers to the definition of a measure. The turnaround time for a process under consideration has been defined as X% emails getting answered within 24 hours. Moreover, customer satisfaction has been defined and quantified as X% of the customers rating service provider at a score of 90% and above.

How do we record the measurement?

The fourth element of the operational definition worksheet refers to the method of recording the measurement. The data related to customer satisfaction shall be recorded from the C-Sat report provided by the third party vendor. The score assigned to Customer Verbatim in C-Sat report shall be final.

How to Develop Operational Definition Worksheet in the Measure Phase?

Let’s discuss the process of developing an operational definition worksheet in the measure phase.

1) Identify the characteristic to be measured

The first step is to identify the characteristic we are interested in. In other words, during the measure phase, we have to identify the characteristic we want to measure or the defect type of concern.

2) Selecting the measuring instrument

The second step in developing an operational definition worksheet is to select the measuring instrument of the measure phase. The measuring instrument is either a physical piece of measuring equipment (such as a micrometer, scale, or a clock) or a visual check. We may want to include standards; if we are doing a visual check. For example, we may be judging the color of a product. We should include standards that indicate the acceptable color range

3) Describe the test method

The third step in developing an operational definition worksheet is to describe the test method of the measure phase. The test method is an actual procedure used for taking the measurement. When measuring time, start time and end time of the test need to be specified. When taking any measurement, the degree of accuracy needs to be stated without fail. For instance, it is important to know whether turnaround time will be measured in hours, minutes and seconds or only in hours and minutes.

4) State the decision criteria

The fourth step in developing an operational definition worksheet during the measure phase is to state the decision criteria. The decision criteria represent the conclusion of the test. Does the problem exist? Is the item correct? Whenever a visual check is used, a clear definition of ‘Acceptable’ versus ‘Unacceptable’ is essential. Physical examples or photographs for the acceptable and unacceptable, together with written support, are the best definitions.

5) Document the operational definition

The fifth step in developing an operational definition worksheet is to document the operational definition. It is important that the operational definition is documented and standardized in the measure phase. Definitions should be included in training materials and job procedure sheets. The results of steps 1 through 4 should be included in one document. The operational definition and the appropriate standards should be kept at the work station.

6) Test the operational definition

The sixth step in developing an operational definition worksheet is testing the operational definition. It is essential to test the operational definition before implementation during the measure phase. Input from those that are actually going to complete the tests is particularly important. The operational definition should make the task clear and easy to perform. The best way to test an operational definition is to ask different people to complete the test on several items by following the operational definition. We can watch how they perform the test.

When looking at how they took the measurements in the measure phase, one has to ask the following questions:

- Firstly, are they completing the test as expected?

- Secondly, are the results consistent?

- Finally, are the results correct?

And that is how you design an operational definitions worksheet in the measure phase. Having a standardized protocol or operational definition worksheet for taking measurements is vital for Six Sigma measure phase. These Six Sigma projects are data driven and the success of a project depends on the accuracy of the data. A good operational definitions worksheet will enable the Six Sigma practitioner to collect accurate and reliable data.

2 thoughts on “Why Operational Definition is Important in Six Sigma Measure Phase?”

Comments are closed.