Lean Six Sigma Green Belt training mostly focuses on the Six Sigma framework of DMAIC which is specifically designed for improving existing processes. But what happens if a process needs to be completely re-designed in order to bring improvement? While it is not often discussed in a brief free Six Sigma training, there is another Six […]

Tag: DMAIC

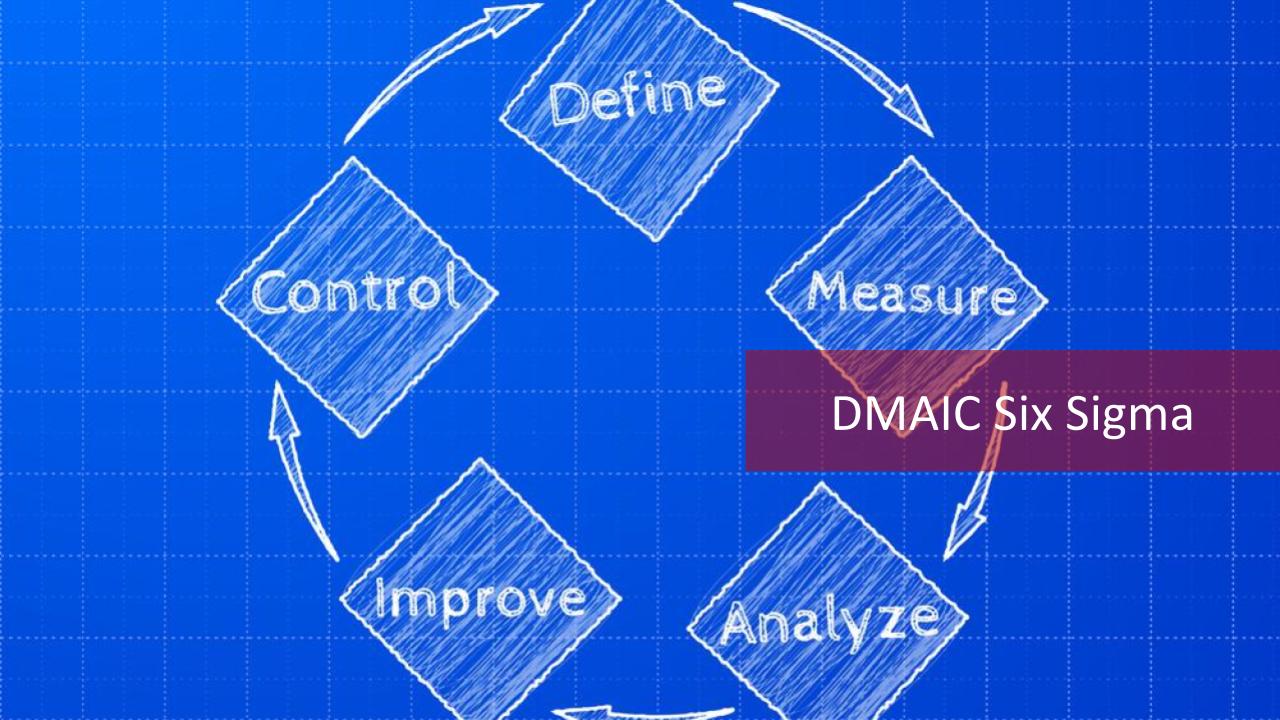

The DMAIC Approach: 5 Phases of Six Sigma

Six Sigma is a problem-solving process that is used by engineers and other professionals worldwide. The Six Sigma process is a structured, data-driven approach to problem-solving. There are many aspects to the 6 Sigma ranging in difficulty which is why there are levels of Six Sigma Certification: green belts, black belts, and master black belts. […]

Process Mapping Techniques and Important Tips

There are many Six Sigma tools that are covered in Lean Six Sigma Green Belt training. One of the most important processes of the Six Sigma Define phase of the DMAIC cycle is Process Mapping. Process mapping is one of the fundamental Six Sigma principles that are shortly covered in free Six Sigma courses. But […]

Measures of Central Tendency: Mean, Median & Mode

Statistics. While others might stifle a yawn at the mere word, Six Sigma practitioners who have passed the Lean Six Sigma Green Belt course knows that without statistics, no Six Sigma project will succeed. Statistics is simply part of the data-driven Six Sigma approach. At the Six Sigma Green Belt level, we need to have […]

9 Steps For Constructing The Fishbone Diagram

The Cause-and-Effect Diagram is one of the Six Sigma 7 QC Tools. It goes by several names, the most popular being a Fishbone Diagram because a completed diagram resembles the skeleton of a fish. It is also sometimes referred to as an Ishikawa Diagram after its creator. Leading online six sigma courses and Lean Six […]