There are many different terminologies in the world of Six Sigma. When we talk about Six Sigma, you will hear those words often: normal distribution, DMAIC, FMEA and so forth. The Six Sigma approach involves optimizing or improving a process to have as little defects as possible. That is why one of the most important terms in Six Sigma is the term Defects per Unit (DPU). It is important for Green Belt Certification to have knowledge of terms like DPU. Online Six Sigma courses and also free Lean Six Sigma training can easily clarify any confusion over terminology.

Attend our 100% Online & Self-Paced Free Six Sigma Training.

In this article, we’ll explore the term DPU to understand its definition and its role in the Six Sigma process.

We will go through following points one-by-one about DPU metric.

- Definition of the word ‘Defect’ in Six Sigma

- What is Defects per Unit (DPU)

- Three steps to calculate process’s Defects per Unit (DPU)

- Defects per Unit (Formula and Illustration)

What is the definition of “Defect” in Six Sigma?

Before we move on to our metric, DPU, let us first understand what the meaning of the word ‘Defect’ is in the context of Six Sigma methodology. Defects play a central role in the Six Sigma methodology because the goal of many Six Sigma-DMAIC based projects is to improve process performance and customer satisfaction by reducing the defect rate. Please note each and every defect has to meet one or more parameters of S-M- A-R- T criteria.

A defect is defined as “anything outside of customer specifications”. In other words, a defect means any event or transaction that does not meet the customer requirement. A defect should also be thought as a failure to meet the customer expectations for quality. A central tenet of the Six Sigma methodology is that the customer defines quality. In other words, quality is what the customer perceives.

To take an example of a defect, a tailored shirt or trouser that is too long or too short, is against what customer had specified and would be a defect. Pizza delivery that takes very long is a defect. Unclear channel in a DTH service is a defect. Please note a catch here: the existence of one or more defects in a process, product or service does not necessarily mean that the process or product is defective. The word ‘Defective’, in Six Sigma terminology, means the failing of the entire process, product or service. For example, if a new car in the showroom has a minor dent on one side of its body, then it has a defect. However; the car will be considered as defective if one or more customers refuse to buy it on account of that defect.

What are Defects per Unit?

DPU is a metric that expresses how your product or process is performing, based on the number of defects. DPU refers to the average number defects per sampled unit of product or service. DPU evaluates the average number of units carrying one or more defects. For the purpose of this metric, don’t forget to quantify the defects under consideration.

Let us also try to understand what the word ‘Unit’ means in Six Sigma methodology. A unit is an item being processed. DPU counts each unit as either defective or not defective. Here the word ‘Defective’ refers to units carrying one or more defects.

How to calculate DPU?

Let us now have a look at three steps to calculate process’s DPU.

- The first step is to determine the total number of units you will sample. It means determining the sample size. A sample group should be small enough to be manageable, yet large enough to reflect the problem that is disturbing the process under consideration

- The second step is to count the number of defects or errors that occur within the sample. In other words, you will need to determine how many units in the sample group contain at least one defect or error.

- The third step gives you the DPU as a decimal number, which can be converted to a percentage

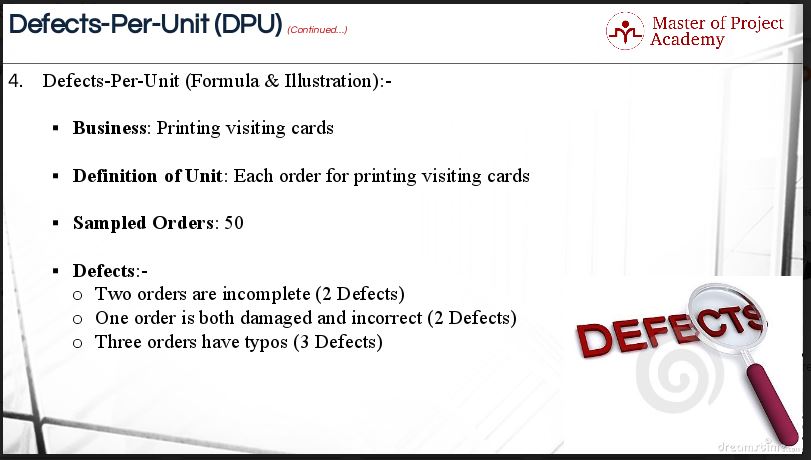

Let’s look at a quick illustration of how to calculate DPU. Mr. X has got the business of printing visiting cards. Each order is considered as a unit. Fifty orders have been randomly selected and inspected. Out of the fifty orders, six orders have a problem, and there are a total seven defects out of fifty orders that have been sampled.

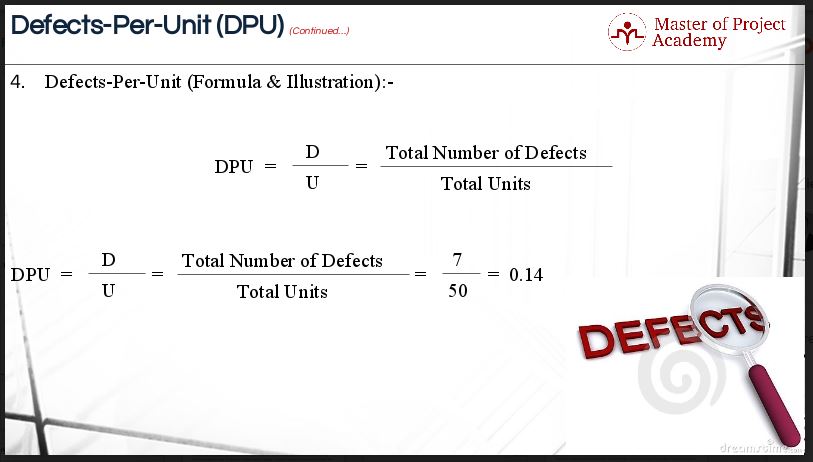

Let us have a look at the formula for calculating DPU. The formula is the total number of defects divided by the total number of units sampled or inspected. Therefore; the DPU in this example is equal to seven divided by fifty. The answer is 0.14. The conclusion is: On an average, each unit of product cont a ins 0.14 defects. That is it!

DPU is an important term to learn if you want to do a Six Sigma project. It is the basis of what you want to change in a process. It is the measure of what is wrong with the process, and the number of DPU will guide you to realize whether you have improved the process sufficiently. DPU shows you how efficient a process is regarding producing products that deliver on customers’ expectations. After all, that is the main reason why we use Six Sigma – to reduce variation and defects that impacts of customer satisfaction and ultimately on the bottom line.

Review by: Micheal Jordan

One thought on “Defects Per Unit (DPU): The Crux Of Six Sigma”

Comments are closed.