In online Six Sigma course, we learn that the success of every Six Sigma project is determined by how well the process improvement increases customer satisfaction. The Six Sigma principle is based on the notion that a process should consistently deliver outputs that are within customer requirements. We determine the customer demands in the Six Sigma Define Phase of the DMAIC structure of Six Sigma projects as briefly discussed in free Lean Six Sigma training. However, the definition of customer requirements is not so simple. Let’s discuss an interesting topic, the KANO model.

Attend our 100% Online & Self-Paced Free Six Sigma Training.

Customers do know what they want but may not be proficient at describing their needs. The KANO model identifies three types of customer needs. By understanding the three types of customer needs and how to reveal them with the KANO model, the project team can use this information to guide the improvement process.

The development of the KANO model Six Sigma

Noriaki Kano, a Japanese researcher and consultant, published a paper in 1984 with a set of ideas and techniques that help us determine our customers’ satisfaction with product features. These ideas are commonly called the KANO Model. The KANO model Six Sigma shows that there is a basic level of quality that consumers assume the product will have. When listening to Voice of Customer, the team might classify the data into three categories. The categories are Must-be, Primary Satisfiers, and Delighters. This classification is called a KANO Analysis.

- A must-be requirement can dissatisfy, but cannot increase satisfaction. It is a basic requirement of the customer; they will not do business without it.

- A Primary Satisfier requirement is one where the more of these requirements that are met, the more satisfied the customer

- A delighter does not cause dissatisfaction if not present, but it will delight clients if present

The team must ensure that the process meets the must-be’s, increases the primary satisfiers, and potentially adds delighters.

Example

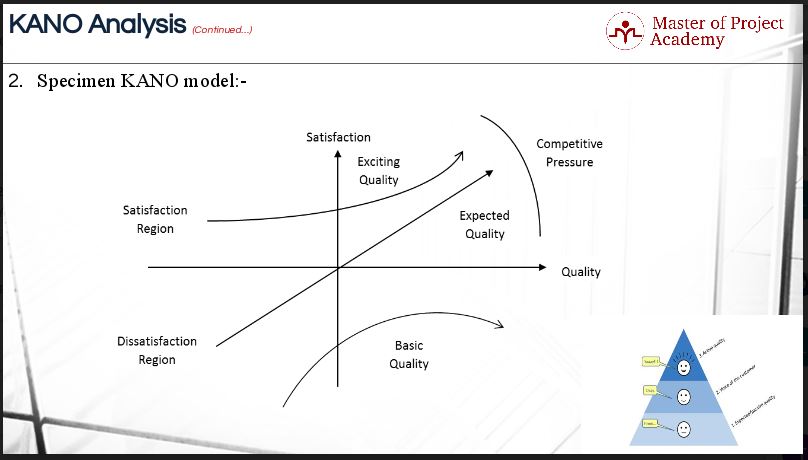

Please have a look at an example of a KANO model. This is what the diagram looks like.

How does it work?

The KANO model shows that there is a basic level of quality that customers assume the product will have. For example, all cars have windows and tires. If asked, customers don’t even mention the basic quality items, they take them for granted. However, if this quality level isn’t met the customer will be dissatisfied.

KANO model – Basic and Expected Quality

Note that the entire ‘Basic Quality’ curve lies in the lower half of the chart, representing dissatisfaction. Providing basic quality is not enough to create a satisfied customer. The ‘Expected Quality’ line represents those expectations which customers explicitly consider. The model shows that customers will be dissatisfied if their quality expectations are not met; satisfaction increases as more expectations are met.

KANO model – Exciting quality

The ‘Exciting Quality’ curve lies entirely in the satisfaction region. This is the effect of innovation. Exciting quality represents unexpected quality items. The customer receives more than they expected. Competitive pressure will constantly raise customer expectations. Today’s exciting quality is tomorrow’s basic quality.

Keeping up with changing customer expectations

Firms that seek to lead the market must innovate constantly. Conversely, firms that seek to offer standard quality must constantly research customer expectations to determine the currently accepted quality levels. It is not enough to track competitors since expectations are influenced by outside factors as well. For example, the quality revolution in manufacturing has raised expectations for service quality as well.

Instructions to prepare KANO model

Here are the instructions to prepare KANO model:

- Generate a list of customer requirements. Don’t guess what they are – talk to your customers

- Review the KANO model

- Identify the appropriate category for each requirement. Work through the list of requirements one by one.

- Mark each product or service attribute as to whether it is a: disatisfier/basic requirement, satisfier/more is better or a delighter. Add a fourth category – not relevant. These are attributes that the customer does not care about.

- Determine priorities

How to determine priorities in a KANO model

- First look at anything labeled as dissatisfiers or basic requirement. These represent customers’ minimal expectations, assess whether your organization is currently filling these requirements or not

- Perform the same assessment on the satisfiers. Are you doing them at all? Can you do more?

- If you aren’t meeting the basic requirements and have a lot of work to do on the satisfiers, don’t worry about the delighters yet. If you have all the basic requirements covered, and most of your satisfiers are done well, evaluate the delighters

Improve your process considering the results from the KANO model

Now that you have done the KANO Analysis using the KANO model, you can target your improvement project to ensure that it meets all the basic requirements and most of the satisfiers. If your improvements covered all of the satisfiers, try to see how many delighters you can incorporate within budget. Be realistic about what you can offer consumers. Do not sacrifice basic requirements of satisfiers to include more delighters as defined by the KANO model. KANO model delighters are usually more exciting, and while they may let your product stand out from the crowds, they will not lead to more sales if your product lacks the basic requirements. It is more important to get the basics right. The KANO model helps to identify what those basics are and helps Six Sigma teams to focus on the most important factors during the process improvement process. There are many Six Sigma tools available to Six Sigma practitioners. The KANO model is a handy tool to prioritize requirements for improvements. Use it wisely and lead the way to a successful Six Sigma project.

2 thoughts on “3 Levels of Quality in KANO Model”

Comments are closed.