Any business that wants to have great quality management and produce quality products that deliver on customers’ expectations will do well to employ staff with Six Sigma Green Belt Certification who have completed classroom or online Six Sigma training. In the Six Sigma approach to problem-solving, a Six Sigma professional will review the process to determine where the points of pain are and how to improve the process. Part of the Six Sigma method is to calculate the total number of defects that the process delivers. There are various metrics used to evaluate defects: Defects per Unit (DPU), Defects per Opportunity (DPO), and Defects-per-Million-Opportunities (DPMO).

Attend our 100% Online & Self-Paced Free Six Sigma Training.

This article will discuss the use of DPMO in Six Sigma. We will go through the following points:

- What is Defects-Per- Million-Opportunities

- 5 steps to calculate process’s Defects-Per- Million-Opportunities

- Defects-Per- Million-Opportunities (Formula and Illustration)

- Why Defects-Per-Million-Opportunities

What Does DPMO Mean in Six Sigma?

Defects-Per- Million-Opportunities, which is abbreviated as DPMO. It is also called NPMO or Nonconformities per Million Opportunities. It is defined as the ratio of the number of defects in a sample to the total number of defect opportunities multiplied by 1 million. DPMO is a long-term measure of process performance. It is a measure of the error rate of a process. The metric tells you how good your process is towards committing mistakes. It requires you to think reversely.

5 Steps to calculate DPMO

There are five steps to calculate the process’s Defects-per-Million-Opportunities. The first four stages of DPMO calculation are similar to that of computing Defects per Opportunity or DPO.

Calculating DPMO: Step 1

The first step is to determine the total number of units to be sampled. In other words, you have to determine the sample group size. As a thumb rule, the sample size should be small enough to be manageable, yet large enough to reflect whatever problem is undermining the process.

Calculating DPMO: Step 2

The second step is to determine the number of defect opportunities per unit. That means, opportunities will have to be defined with the help of the following methods:

- Creating a list of potential defects or errors per unit of process or product or service customers will care about

- Focusing on places or process steps where something can go wrong and not on the ways it can go wrong

- Focusing on routine, rather than rare defects or errors

- Grouping or merging related or similar defects into one category

Going through this process, you have to keep the Voice of the Customer in mind. Some characteristics of the products may be important to clients and others might be nice to have. Focus on the features that will impact customer satisfaction and make sure that the traits are measurable.

Check our Six Sigma Training Video

Calculating DPMO: Step 3

The third step is to determine the total number of defect opportunities ONLY for the sample size under consideration. This is done by multiplying the number of units in the sample group with the number of defect opportunities per unit.

Calculating DPMO: Step 4

The fourth step is to count the defective opportunities within the sample group. You will simply have to calculate how many opportunities within the sample group actually contain defects or errors. It is important to take a sample group that is representative of the population. Also, the sample group must be large enough to be meaningful, but small enough to be manageable.

Calculating DPMO: Step 5

In the fifth and final step, we simply have to divide the total defects by the total opportunities which give us the DPO. Then we multiply the DPO by 1 million to obtain the Defects-per-Million-Opportunities. This value gives us an accurate, long-term, view of the efficiency of the process.

An example of calculating DPMO

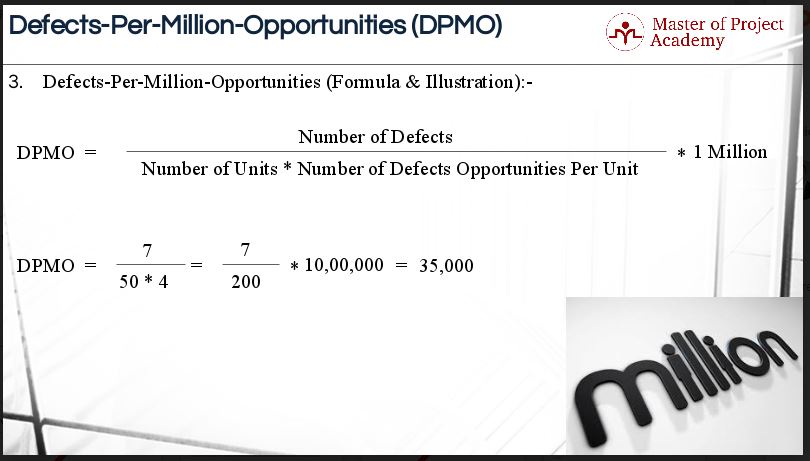

Here you go with a quick illustration that we used for calculating DPO. Mr. X has got the business of printing visiting cards. Each order is considered as a unit. Each order has four defect opportunities i.e. incorrect, typo, damaged or incomplete. Fifty orders have been randomly selected and inspected. Out of the fifty orders, six orders have a problem, and there are a total of seven defects out of fifty orders that have been sampled.

Let us have a look at the formula for calculating DPMO. In your equation, multiply your DPO by 1 million. Have a look at the formula again, it is similar to the formula of DPO except for the final step. Since we are talking about one million opportunities here, we have to multiply the DPO by 1 million to get the DPMO in the last step. Therefore, the DPMO is equal to seven divided by two hundred (which gives us the DPO) and multiplied by 1 million which provides us with the DPMO. The answer is 35,000. The conclusion is: that your process will generate 35,000 opportunities for committing defects or errors when it has produced 1 million orders. Consider this, the best process possible will have a DPMO of zero, while the worst possible process will have a DPMO of 1 million. This gives some context regarding good or bad processes regarding DPMO.

Why DPMO?

Why is it necessary to calculate the DPMO of a process? It gives your business an accurate picture of the efficiency of your process. Depending on the Defects-per-Million-Opportunities, your company can decide whether it is necessary to launch a Six Sigma project that will improve the process and reduce the number of opportunities for defects per million products. If the DPMO is too high, you run the risk of negatively affecting customer satisfaction which in turn will reflect negatively on your business. Six Sigma business improvement projects focus on reducing errors and increasing customer satisfaction and thereby nurturing a healthy business. This is what DPMO means in the Six Sigma approach.

Review by: Jesse Jensen

2 thoughts on “5 Steps for Calculating Defects per Million Opportunities (DPMO)”

Comments are closed.