Lean Six Sigma Green Belt training mostly focuses on the Six Sigma framework of DMAIC which is specifically designed for improving existing processes. But what happens if a process needs to be completely re-designed in order to bring improvement? While it is not often discussed in a brief free Six Sigma training, there is another Six Sigma approach – DMADV – which applies to situations where a process must be re-designed for improvement to take place. What is the difference between these two Six Sigma methods?

Attend our 100% Online & Self-Paced Free Six Sigma Training.

What does DMADV mean?

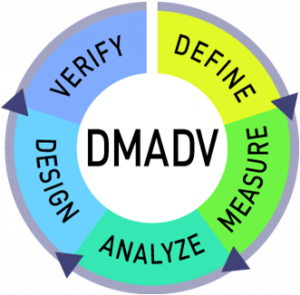

We have seen that DMAIC stands for Define, Measure, Analyze, Improve and Control. Another improvement framework is DMADV and first three letters of this framework are as same as in DMAIC and stand for Define, Measure and Analyze respectively. However, last two letters stand for Design and Verify.

The DMADV framework

Each phase of the DMADV framework is as below:

- Define customer requirements and goals for the process, product or service

- Measure and match performance to customer requirements

- Analyze and assess the design for the process, product or service

- Design and implement the array of new processes required for the new process, product or service

- Verify results and maintain performance

The basic difference between DMAIC and DMADV frameworks is, DMAIC will be used when you are trying to improve or develop a process which is already into existence.

However, the DMADV (Define-Measure- Analyze-Design- Verify) method aims to redesign a problematic process or product. The approach initially follows the first three steps of DMAIC and then deviates in the last two-steps by introducing the Design / Re-design and Verify or Validate steps to gain the improvements needed. This approach prevents problems from happening through quality and robust design concepts.

Let’s look at the different stages of the DMADV framework more closely.

Design

In the first phase, goals are identified regarding the purpose of the project. During this stage, realistic and measurable goals are set that is important to both the organization and its stakeholders. After the goals have been set, a clear scope must be defined for the project and a clear strategy must be aligned with each of the project goals that will satisfy the expectations of the organization and the customers.

Measure

The second step in DMADV is Measure. In this step, the factors that are critical to quality should be measured. It’s important to define the requirements of the metrics. The way in which the metrics will be measured must be well-designed to provide useful answers. It must assess quality, risk, process capability and product capability among others.

Analyze

During the Analyze phase of DMADV, several actions must be taken. These include developing design alternatives, defining the optimal combination of requirements to achieve a value within the given constraints, conceptual designs, identifying the best components and then developing the best design. Here, the total lifecycle cost of the design is calculated. During the analyze phase we must ask ourselves – what is the best design that will help us meet our goals?

Develop

The fourth stage of DMADV involves a high level and a detailed design for the design that was selected in the previous phase. Each element of the design is assigned a priority after which a high-level design is developed. After a high-level design has been obtained, a more detailed design will be constructed as a prototype. Here, any errors which may occur can be identified and the new process design can be modified to avoid errors.

Verify

Now, in the last phase of DMADV, it is time for the team to verify whether the design is acceptable. Can the design be used in the real world? Pilot studies will need to be conducted as well as production-scale studies. Here it is important to ensure that the absolute best quality possible can be obtained. That is after all the whole point. The Verify step of DMADV also includes an implementation plan that stipulates how the new process will transition into routine operation.

The difference between DMADV and DMAIC

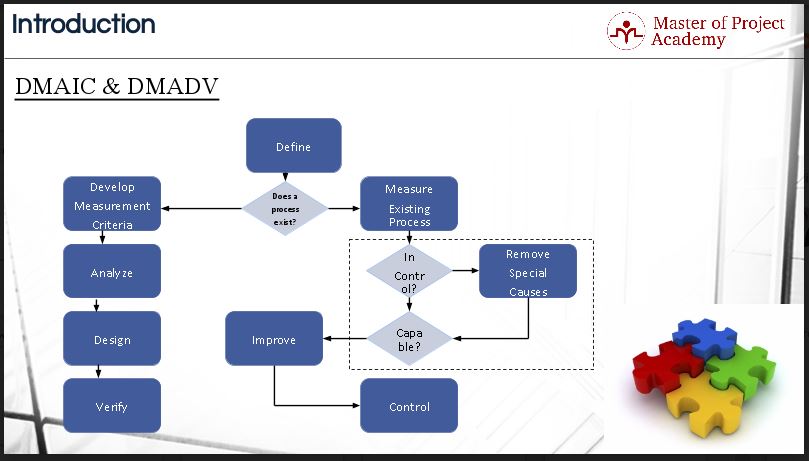

This flowchart represents how DMADV and DMAIC frameworks differ from each other. As you see in the flowchart, after the Define phase, based on the existence of the process, if it is an existing process, DMAIC framework is followed, if it is not an existing process, then DMADV framework is followed.

There is more to it than this flowchart though. Let’s look at some more differences between DMADV and DMAIC.

- DMAIC is about minimizing variation in an existing process while DMADV is about producing a process that is “first time right:”

- DMAIC is correction while DMADV is prevention

- DMAIC uses quantitative statistical tools while DMADV uses qualitative tools like KANO models

- DMAIC focusses on the critical few QTC parameters while DMADV focusses on all of them

- DMAIC is generally a shorter term project than DMADV which is more long term.

It is important to note that Six Sigma is not limited to a specific type of process or problem. While most examples given are from a manufacturing environment, Six Sigma can be applied to improve any process in any environment. It is also not limited to improving an existing process but can be used to design completely new processes as we have seen in this article. DMADV is a useful way to use Six Sigma to think outside of the box and to completely re-design processes that are so broken that they cannot be fixed with the usual DMAIC approach.

Review by: Nathaniel Castillo

One thought on “What is the Difference Between DMAIC and DMADV in Six Sigma?”

Comments are closed.