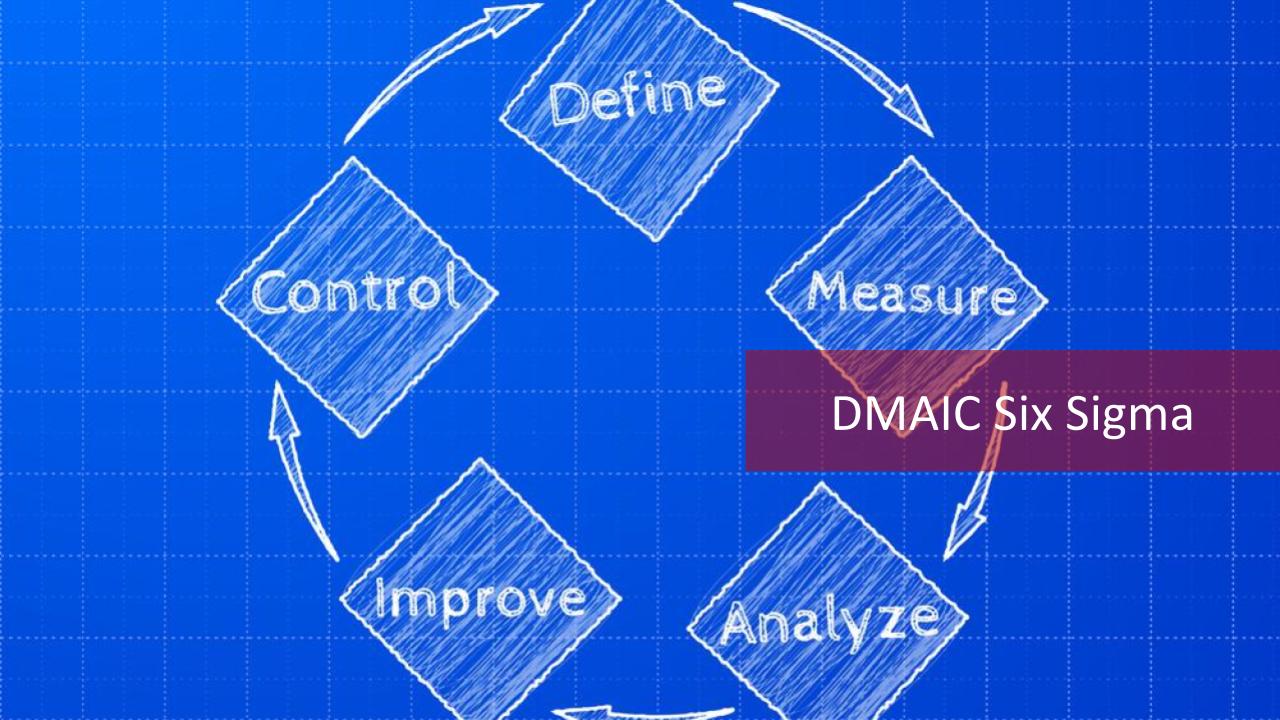

There are many project management tools in Lean Six Sigma. Green Belt training provides a wealth of tools to navigate your Six Sigma project through the DMAIC approach. One of the crucial project management tools that are used early on in the Six Sigma approach is the Stakeholder Analysis. The stakeholder analysis helps to understand […]

Category: Six Sigma

What is LEAN Management and How it is Used to Eliminate Waste?

If you were quite interested in quality management or Six Sigma projects previously, you should have heard about Lean Management or Lean Six Sigma. But what is Lean Management? It was started by Taiichi Ohno at Toyota. It is also known as the Toyota Production System: Lean Management derives its methodology from the Toyota Production […]

7 Facts About Six Sigma Green Belt Certification

If you are working in the quality management area, you must have heard Six Sigma Green Belt many times. Lean Six Sigma Courses, train the quality management professionals for the Six Sigma Green Belt Certification Exam. But what does Six Sigma stand for and how it defines quality? How does Six Sigma Green Belt will […]

Why Do You Need to Listen to the Voice of Customer?

In Six Sigma Green Belt training, there is a lot of terminologies to learn. Voice of Customer is one of them. Let’s consider the DMAIC structure of Six Sigma projects, and more precisely the DEFINE stage. This is where the scope and purpose of the project are defined. As you may also learn in free […]

The DMAIC Approach: 5 Phases of Six Sigma

Six Sigma is a problem-solving process that is used by engineers and other professionals worldwide. The Six Sigma process is a structured, data-driven approach to problem-solving. There are many aspects to the 6 Sigma ranging in difficulty which is why there are levels of Six Sigma Certification: green belts, black belts, and master black belts. […]